BIMETAL WORKPIECES

Double-layered bimetal sheets

Possibility of bonding of any commercially available metals and alloys.

Parent sheets shall have at least 25% elongation to avoid cracking. Bonding with elongation of less than 25% and without cracking is possible, but in each such case a specific solution is required.

In particular, the explosion welding department has manufactured products with the following combinations of metals:

| Primary layer | Cladding layer |

|---|---|

| Carbon steel | +carbon steel;+stainless steel; +titanium; +brass; +copper; +aluminium; +nickel; +monel; +melchior; +tantalum; +niobium; +cobalt |

| Stainless steel | +aluminium; +titanium |

| Titanium | +copper; +carbon steel; +platinum; +molybden; +niobium; +cobalt;+tungsten |

| Aluminium | +copper; +titanium |

| Copper | +carbon steel; +stainless steel; +titanium |

| Brass | +aluminium |

| Niobium | +tantalum; +tungsten; +molybden |

| Tungsten | +molybden |

| Tantalum | +molybden |

| Hafnium | +zirconium; +titanium |

| Silver | +copper |

Versions: D16-VT1-0, AMc-12H18N10T, AMg6-VT1-0, AMg6-12H18N10T, AMg6-03H18N10HT, AMg5-12H18N10T, 1545-12H18N10T, 1201-12H18N10T, 12HМ+08H18N10T, 09G2S+08H13, 09G2S+06HN28MDT (904L), 09G2S+L63, D40+AMG6, 09G2S+08H13, 09G2S+L63, 09g2s+LO62

Overall dimensions: : subject to agreement with the customer (width up to 2000 mm, length up to 8000 mm, thickness from 10 to 200 mm (from 0.5 to 30 mm for cladding layer)

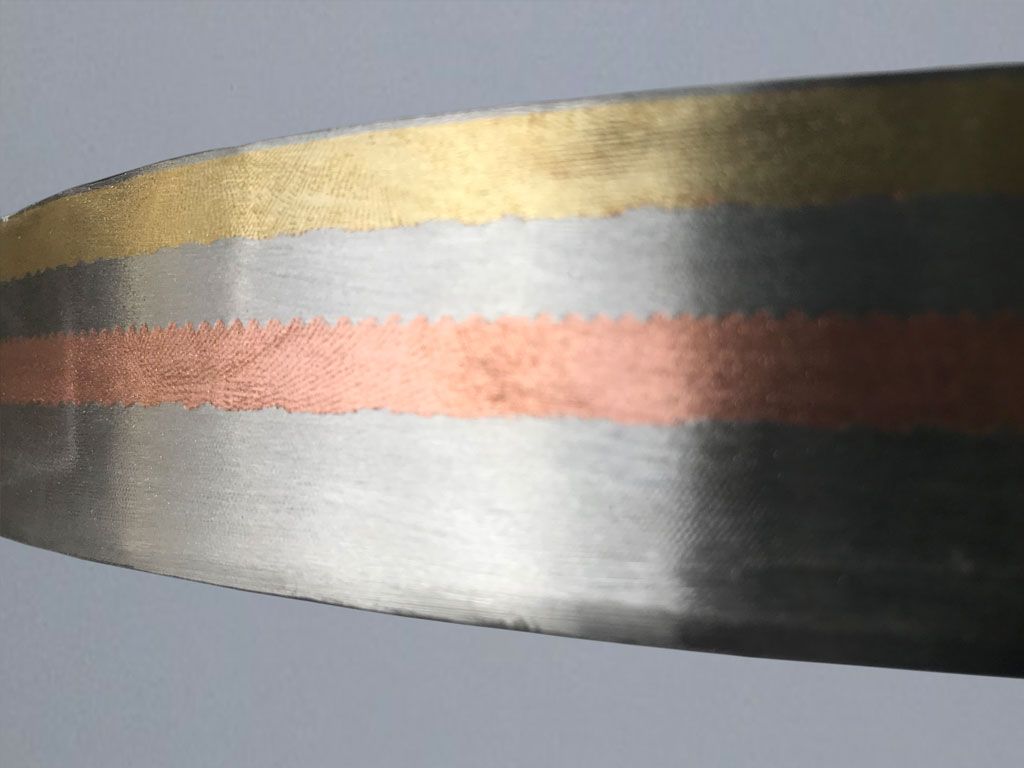

Multi-layered bimetal sheets

Possibility of bonding of any commercially available metals and alloys.

Make examples:

| Grade | Size, mm |

|---|---|

| M1+AD0+M1 | (5+30+5)х1300х2000, (5+60+5)х1250х1800, (5+65+5)х1200х1700 |

| M1+VT1-0+M1 | (4+4+4)х600х1500, (5+4,5+5)х400х1400 |

| M1+VT1-0+AD0 | (3+10+5)х500х500 |

| VT1-0+AD0+cadmium | (30+1+1)х400х400 |

| St.3+L63+A020-1 | (6+1+2,2)х160х350 |

| St.08KP+LO62+A020-1 | (5+2+1)х80х290 |

| St.3+08H18N10T +AD0 | (40+1+12)х200х200 |

| 09G2S+03H18N11+03H18N11 | (40+8+8)х1200х1300 |

| 12H18N10T+St.20+М1+12H18N10T | (3+8+5+1)х400х400 |

| Platinum+Titanium+Platinum | (0,5+29+0,5)х200х220 |

Overall dimensions: subject to agreement with the customer (width up to 2000 mm, length up to 8000 mm, thickness from 10 to 200 mm (from 0,5 to 30 mm for cladding layer)

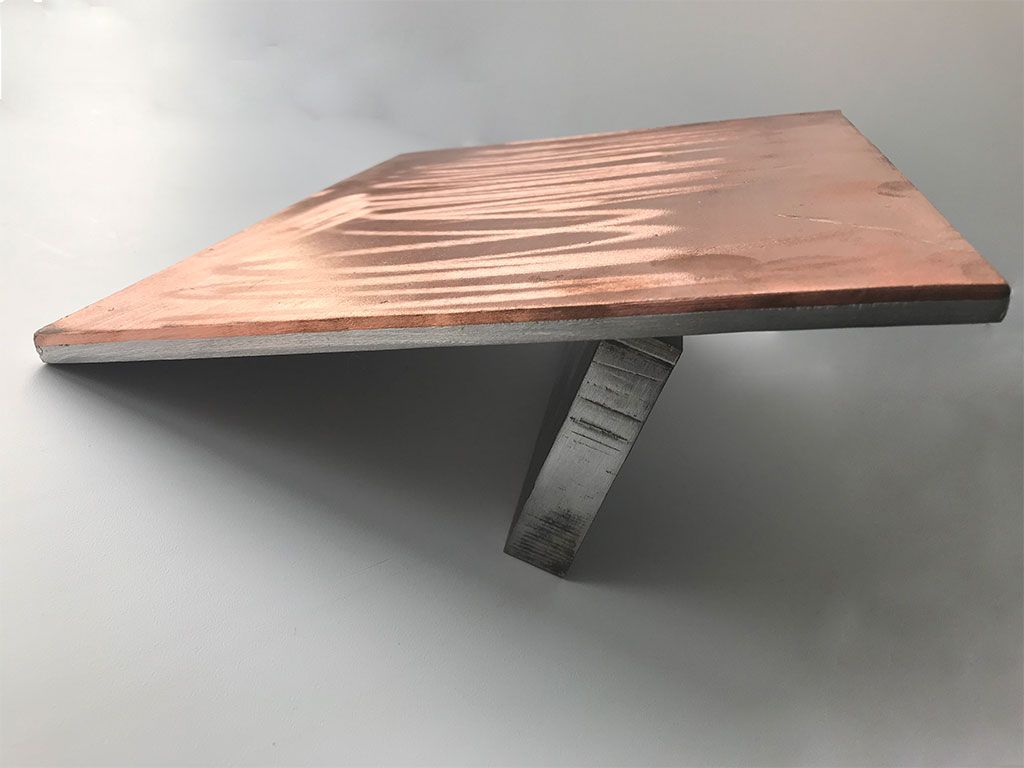

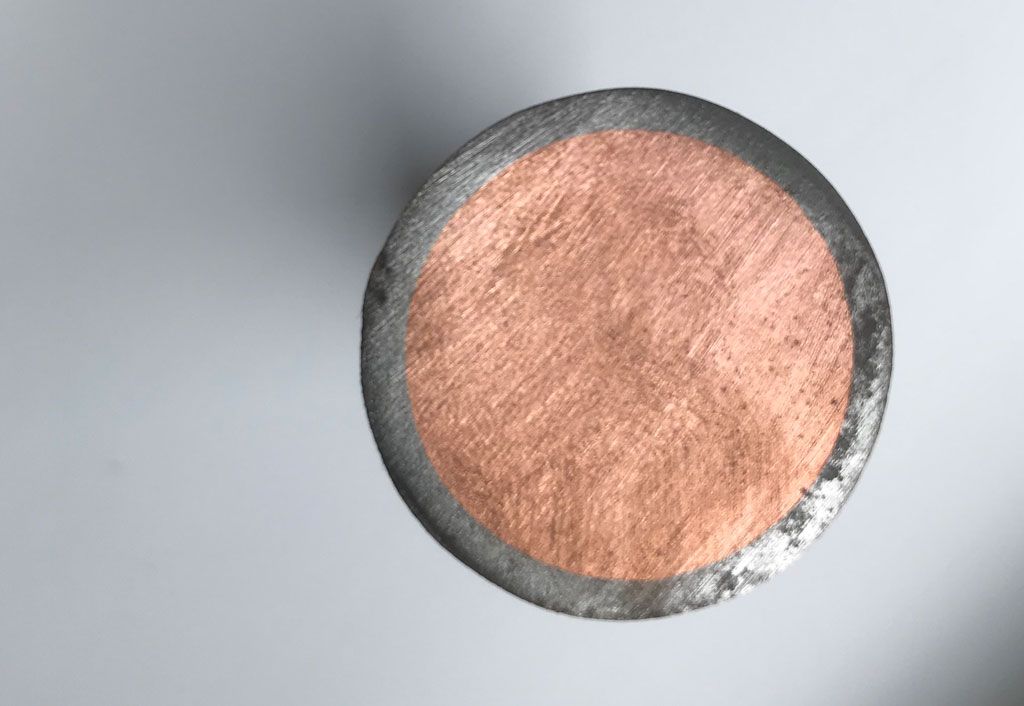

Bimetallic rods

Bimetallic rods with a copper core and titanium sheath made of VT1-0 OST 190013-81 titanium are used as conductors operating in a corrosive medium.

The device is used in anodes of new design during production of nickel. In the example, titanium layer thickness is 2 mm, copper rod diameter is 16 mm, and stem length is 1400 mm.

Versions: M1+St.3; M1+12H18N10T; M1+VT1-0, Brass+AD0, Copper+Aluminium

Sizes: Customized production is available

FIND OUT PRODUCTION TIME AND PRICE!

TURNKEY COMPOSITES

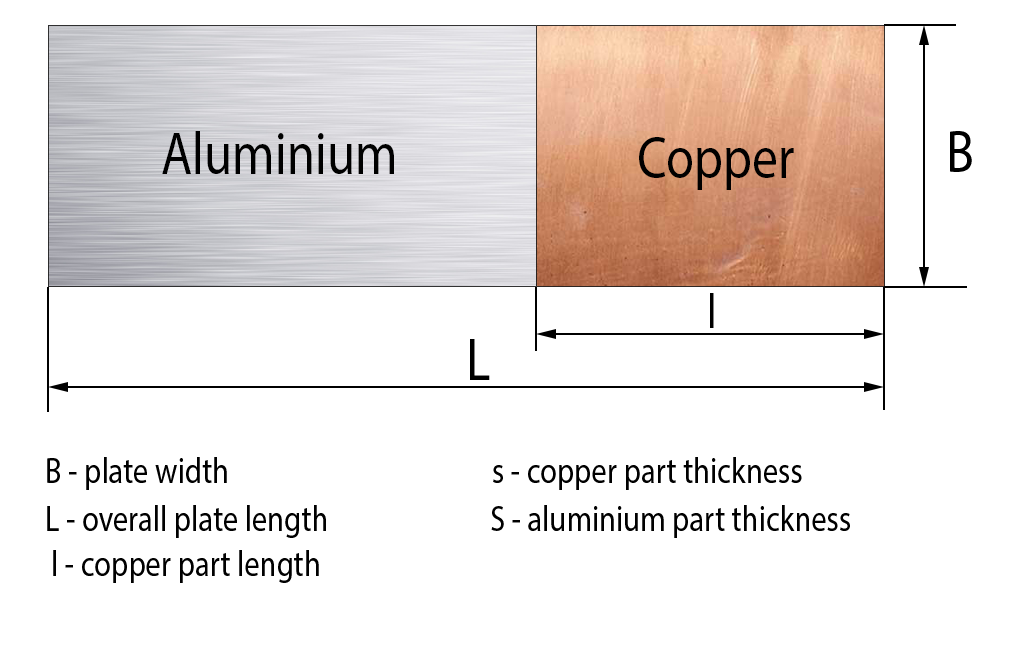

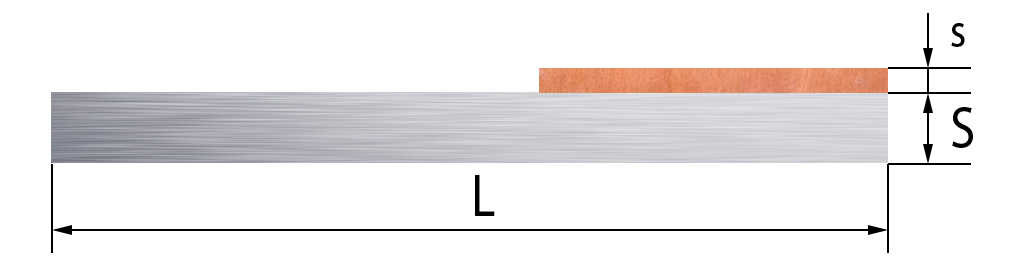

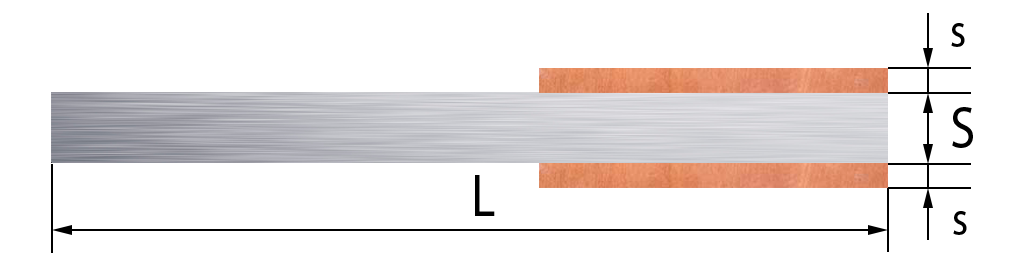

Copper-aluminium MA and MAP plates

(top view)

(side view)

(side view)

Dimensions of MA and MAP copper-aluminium plates in line with GOST 19357-81

| Plate types | Plates width, mm | Aluminium part thickness (primary layer), mm | Copper part thickness (cladding layer), mm | Overall plate length (aluminium part), mm | Copper part length (cladding layer), mm |

| B | S | s | L | l | |

| MA 40-4 | 40 | 3 | 1,5 | 160 | 60 |

| MA 50-6 | 50 | 5 | 1,5 | 160 | 60 |

| MA 60-8 | 60 | 6 | 1,5 | 240 | 80 |

| MA 80-8 | 80 | 6 | 1,5 | 250 | 90 |

| MA 100-10 | 100 | 8 | 1,5 | 270 | 110 |

| MA 120-10 | 120 | 8 | 1,5 | 320 | 140 |

| MAP 60-10 | 60 | 8 | 1,5 | 300 | 150 |

| MAP 80-10 | 80 | 8 | 1,5 | 300 | 150 |

| MAP 100-10 | 100 | 8 | 1,5 | 300 | 150 |

| MAP 120-10 | 120 | 8 | 1,5 | 300 | 150 |

WHY CHOOSE US?

Experience

Materials quality assurance

Delivery

Wide range of products

It is convenient to work with us

Best price offers

QUALITY ASSURANCE

Bimetal quality is ensured by:

- Input control of parent materials;

- Manufacturing technology;

- System of monitoring of process parameters at all stages of production;

Finished bimetal is exposed to the following scope of testing:

- Ultrasonic control of joint continuity;

- Control of joint tensile, shear and bending strength;

- Ultrasonic and metallographic control of cladding layer thickness;

- Control of nonflatness;

- Control of primary layer mechanical characteristics at the Customer’s request.

ABOUT US

Protol LLC manufactures double-layered and multi-layered compositions from different metals and alloys by way of explosion welding.

Highly qualified staff (including two Candidates in Technical Sciences) with many years of ample experience in the area of explosive metal forming can develop and bring to commercial production the required volume of products with specified quality within as short a time as possible.

In particular, we can manufacture and deliver to any region in the Russian Federation or CIS countries large-size bimetal sheets or bimetal products.

OUR CLIENTS

WE WORK WITH THE FOLLOWING COMPANIES

ANY QUESTIONS?

Ask the manager:+7 (343) 379-09-99